Antibody drug conjugate programs are growing fast in oncology because they combine selectivity with high potency. An antibody drug conjugate links a tumor-binding antibody to a potent small-molecule payload through a designed chemical linker. The aim is to deliver most of the payload to antigen-expressing cancer cells, reduce broad exposure, and improve the therapeutic window. The value depends on whether the biology and chemistry stay aligned.

Targeted therapy for cancer: why ADCs are rising now

Many tumors still escape single-pathway inhibition, even with better biomarker selection. ADCs fill this gap well because they do not rely solely on blocking a signal. Binding brings the conjugate to the tumor surface, internalization moves it into the cell, and intracellular processing releases the payload, which then drives cell death.

Target selection goes beyond confirming antigen presence. It depends on antigen density, consistency of expression across lesions, and efficient internalization of the antibody-antigen complex. High shedding targets can soak up the drug in circulation and reduce tumor delivery. Targets with meaningful expression on essential normal tissues can narrow the safety margin.

Bystander effect and resistance in plain terms

A bystander effect can help when tumors are heterogeneous, because the payload released in a targeted cell can reach nearby antigen-low cells. It can also raise off-target toxicity if release happens outside the tumor. Resistance can emerge through antigen downregulation, impaired internalization, altered lysosomal processing, or drug efflux, so these risks are best explored early in ADC drug development.

Bioconjugation: where chemistry sets consistency

Bioconjugation decides how uniformly an antibody drug conjugate behaves batch to batch. Traditional conjugation attaches payloads to accessible lysines or reduced interchain cysteines. These routes are proven, but they can generate heterogeneous mixtures that differ in conjugation site and payload load, which complicates analytics and stability interpretation.

Site-specific bioconjugation aims to reduce that heterogeneity. Common approaches include engineered cysteines, enzymatic tagging, and glycan-directed methods. More uniform conjugates can show more predictable clearance and potency, which becomes valuable when batches get larger.

Linkers, stability, and release

Linkers are often described as cleavable or non-cleavable, but the practical question is where the dominant cleavage happens. Cleavable linkers may respond to lysosomal proteases, acidic pH, or intracellular reducing conditions. Non-cleavable linkers rely on antibody catabolism to generate an active metabolite. The choice affects metabolite identity and impurity families that must be tracked through adc drug development.

Drug to antibody ratio and what it really controls

Drug-to-antibody ratio is a key attribute for any antibody drug conjugate. Higher drug to antibody ratio can improve cell killing, yet it can also increase hydrophobicity, aggregation risk, and faster clearance. Lower drug to antibody ratio can improve stability and tolerability, but may require a higher dose or a more potent payload.

Average drug to antibody ratio is only part of the picture. The distribution of 0, 2, 4, 6, or 8 loaded species can influence aggregation and sometimes antigen binding. For many programs, controlling the drug-to-antibody ratio distribution is as important as controlling the mean.

Antibody drug conjugate manufacturing: translating design into supply

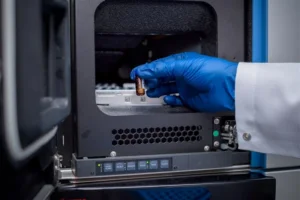

Antibody drug conjugate manufacturing blends biologics processing with high-potency chemistry and tight containment. Upstream and purification steps must deliver an antibody with controlled aggregates and charge variants, because these features influence conjugation efficiency and stability. Conjugation then introduces controlled reduction or activation steps and a strict need to keep the free payload below defined limits.

Conjugation and purification, without overcomplicating it

Mixing and mass transfer matter in antibody drug conjugate manufacturing. If payload addition is too fast, local overloading can increase high-DAR species and aggregation. If reduction is uneven, disulfide scrambling can shift structure and create hard-to-clear variants. pH, temperature, and reaction time shape the final drug-to-antibody ratio profile.

Purification after conjugation removes free payload and process reagents, and it can tighten the product distribution. Hydrophobic interaction chromatography, mixed-mode chromatography, and tangential flow filtration are commonly used, with the sequence depending on payload and linker chemistry. A batch that looks acceptable by a single purity metric can still carry risk if residual free drug or high-DAR tails remain.

Analytics that connect chemistry to patient risk

Release testing for ADCs blends biologics and small-molecule analytics. Intact mass and peptide mapping support identity and conjugation mapping. HIC and LC-MS help quantify drug to antibody ratio and its distribution. Free drug measurement, aggregation, and subvisible particle testing reduce safety risk.

An ADC services overview connects discovery, conjugation, and analytics. This is where bioanalytical laboratory solutions add value, because orthogonal methods can catch subtle shifts early and support comparability across process updates.

ADC drug development: what “precision” needs behind the scenes

ADC drug development works best when biology, chemistry, and CMC (Chemistry, Manufacturing, and Controls) are treated as one decision chain. Target selection is refined with expression data and internalization kinetics. Linker and payload choices are aligned to tumor biology and the desired bystander effect. Bioconjugation is selected for the right balance of manufacturability and product consistency. Then, antibody drug conjugate manufacturing is built around controlling the attributes that drive exposure and safety, especially drug to antibody ratio, linker stability, and free payload.

Scale-up is the stress test. Small shifts in mixing energy, hold times, or filtration sequence can widen the DAR distribution or shift impurity families. When that happens, clinical behavior can change even if the batch record looks similar. It is frustrating, but it is a real constraint.

A steady antibody supply also matters. Consistent antibody production services reduce variability at the starting point, making conjugation more predictable and release testing more straightforward.

A realistic view of precision

The rise of the antibody drug conjugate reflects a practical need: more focused tumor killing with workable tolerability. ADCs can deliver this targeted therapy for cancer, but only when target biology, bioconjugation, and antibody drug conjugate manufacturing are treated as a single system. With disciplined control of drug to antibody ratio and linker stability, precision becomes measurable and reproducible.