Summary

Pharmaceutical companies are under immense pressure to develop drugs for unmet medical needs while improving processes to shortentimelines and minimize costs.

This case study explains how Syngene minimized costs while ensuring quick turn-around time when scaling a client’s compound from lab-scaleto cGMP- scale.

Syngene not only delivered as per timelines but also increased yield by 25% and reduced the overall drug product cost by 65%.

About the client

The client is a leading global pharma company that uses innovative science and digital technologies to create transformative therapies.

Its products reach nearly one billion people worldwide. The company is also constantly working to discover new ways to expand treatment access to those who need it the most.

The challenge

Syngene’s chemical development team received a proposal from the client to develop a quick, scalable, safe, and cost-effective process for taking their compound from lab-scale to cGMP-scale.

The compound, developed by the client’s offshore Medicinal Chemistry team, was based on seven linear synthetic steps with a low average yield of around 7%. The process for drug development also comprised five chromatographic purification steps as a result of using toxic and hazardous chemicals during route development.

Additionally, the key starting material (KSM) was quite expensive and likely to jack up the cost of the final drug product.

The client was looking for a suitable route modification process that could demonstrate the scalability and safety of the final drug product at minimum cost.

The project objectives and milestones were as follows:

- Develop a quick, robust, and scalable process suitable for large-scale synthesis

- Deliver 80 to 100 grams as proof of concept (PoC) along with a technology package

- Deliver 1 kg of the drug product under cGMP environment

- Drug development in five to six weeks, followed by PoC and kilo-scale delivery for Tox studies

Syngene’s holistic approach to process development

A team of highly skilled process chemists, analysts, process engineers, process safety engineers, quality, production, and project management came together to decide on a holistic approach to process development. This included the following:

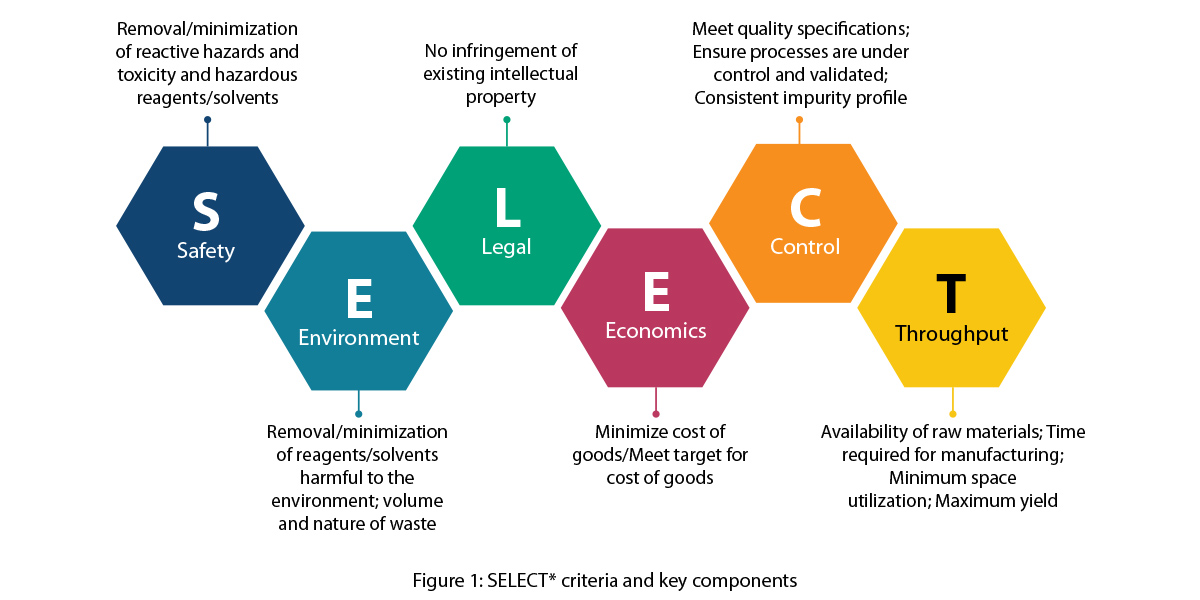

- Review of the current process in detail and listing out the challenges in terms of safety, yield, impurity profiles, reproducibility, scalability, environment, and process economics using the ‘SELECT’ criteria

- An exhaustive literature survey to support process understanding

- Interpretation of the process in terms of challenges, opportunities, and probable solutions

- Detailed experimental plan with alternate routes based on literature and brainstorming with the team

- Detailed plan split into five sections – process development; process optimization; analytical method development and validation; safety

assessment; scale-up and progress monitoring plan - Activities planned in a series and in parallel, based on the advantages and complexities involved

SELECT criteria – An ideal process condition approach

Syngene decided to adopt the industry standard ‘SELECT’ criteria to ensure a 360- degree approach to process development. This criteria is

extensively used at Syngene across client projects to make sure no parameter is missed out during development and scale-up. The Syngene

team judiciously followed the criteria and came up with a process plan as shown below.

*Butters, M., Catterick, D., Craig, A., Curzons, A., Dale, D., Gillmore, A., & White, W. (2006). Critical assessment of pharmaceutical processes a rationale for changing the synthetic route. Chemical Reviews, 106(7), 3002-3027.

The process would ideally have the following characteristics:

- Minimal number of synthetic steps- preferably convergent routes

- Bare minimum cryogenic operating conditions

- No requirement for special equipment

- High conversion, selectivity, and yield at every step

- Easy isolation methods and robust crystallization steps

- Avoid chromatographic steps wherever possible

- Avoid using hazardous reagents and reaction conditions

- Use low cost and readily available raw materials

- Minimize protecting and deprotecting steps, wherever possible

The Solution: Mapping process to project outcomes

Criteria | Existing Process | The Opportunity | The Solution | Project Outcome |

|---|---|---|---|---|

Economics and throughput | Linear synthesis | High risk associated with each step and need for quick turn-around time | To make the route more

convergent to minimize process

risk | Developed a convergent route

with minimal tweaking and

reduced risk towards delivery |

Economics | Overall yield of around 7 % | • Uneconomical and low yield • Need for atom economy | Process optimization via DoE

(Design of experimentation)

methodology | • Optimized the process via DoE • Established process parameters having statistical significance • Demonstrated higher yield and selectivity (> 25%) |

Safety, economics, and environment | High solvent volumes and

class- 1 solvent employed in one

of the process steps | • High solvent volumes

posing economic

challenges • Class 1 solvent posing high toxicity levels and deleterious environmental effect | • Bring down the volumes based

on process optimization • Eliminate Class 1 solvent with appropriate Class 3 solvent through solvent screening study | • Solvent volumes reduced by

1/3, Reagents by 2/3 • Class-1 solvent replaced appropriately with Class-3 solvent |

Throughput, environment, and economics | Chromatographic purification steps | Highly unscalable

process, especially for

commercial supplies | • Explore the in-situ process

wherever possible and minimize

the need for purification till the

end. • Develop crystallization process wherever possible | • Successfully eliminated 4 out of

5 chromatographic steps

• Developed in-situ process

through a crystallization

process

• Achieved purity requirement

of around 95-98% for the final

drug product |

Safety and

environment | Use of toxic

and hazardous

compounds | Safety risk from handling

the drug product on a

large scale | • Assess the risk through

systematic safety studies such

as desktop screening and

quantitative methods • Develop a comprehensive risk assessment program | • Conducted detailed

quantitative risk assessment

using DSC, RC1e, vent sizing,

and so on to arrive at a holistic

process condition

• Demonstrated the process at

scale while ensuring minimal

process risk in terms of timely

and safe delivery of the

compound |

Economics | High cost of key

starting material

(KSM) | High impact on process

economics | • Explore alternative KSMs which

are readily available and low cost. • Perform a cost-benefit analysis | • Identified an alternative KSM

for the process which could

perform with equal efficiency. • Reduced costs by 65% • Identified a reliable supplier for uninterrupted supply of the KSM |

Throughput

and control | Absence of

reliable analytical

methods;

Difficult to

reproduce | Reproducibility of the

analysis | • Develop robust analytical

methods using HPLC, GC

wherever applicable | • Developed robust and

analytical methods for

in-process monitoring and final

analysis |

Conclusion

Syngene not only reduced the cost of the final drug product by almost four times but also scaled up operations from lab-scale to cGMP scalein a short span of time.

The process involved identifying a new low-cost starting material and developing a new synthetic route using fewer steps to deliver the final drug product. The new process resulted in an increased yield of around 25% compared to the earlier yield of only 7%. Syngene was also able to reduce solvent volumes and turn-around time while increasing reproducibility. Additionally, we were able to eliminate toxic reagents from the compound, thereby facilitating a safe process. We also identified a supplier for the starting material to ensure uninterrupted supply for the client.

The entire process was developed in five weeks, in tune with project requirements. Syngene delivered 85 gms of the product during PoC stage and also successfully scaled up operations to kilo-scale in a cGMP environment.