In the rapidly evolving landscape of medicine, the dawn of Industry 4.0 has ushered in a new era in biopharma, often referred to as “Medicine 4.0”. Medicine 4.0, which marks a paradigm shift from traditional therapies, has given rise to precision therapies, including gene therapies, mRNA-based therapies, and gene-edited cell therapies. These new treatments hold the promise of targeting specific genetic abnormalities to provide customized treatment solutions to patients. A key component in developing these therapies is the manufacturing of plasmid DNA (pDNA) and the crucial role Contract Development and Manufacturing Organizations (CDMOs) play in ensuring the efficient production of high-quality pDNAs across treatment modalities.

From test tube to bioreactor: The journey of pDNA in Precision Therapies

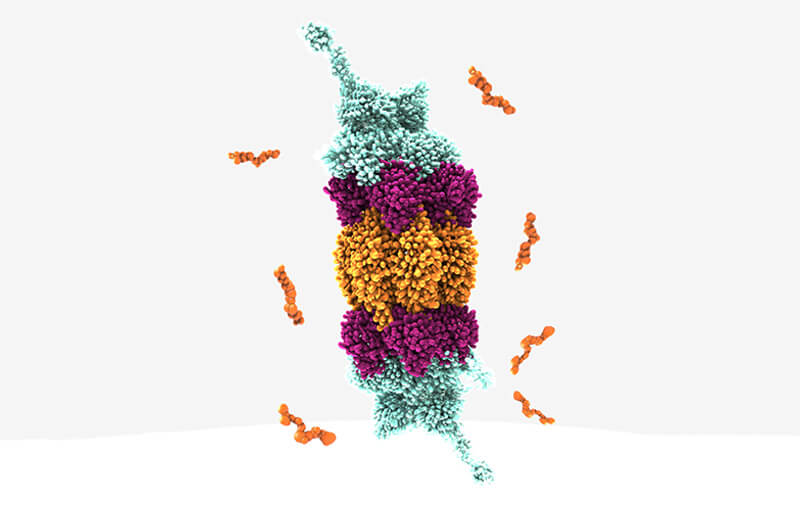

Plasmid DNA (pDNA) has come a long way since its discovery in 1973 when Stanley Cohen successfully used an engineered plasmid to express the tetracycline resistance gene. Over the years, pDNA has become the workhorse of molecular biology. With the advent of Medicine 4.0, it has transcended its role as a research tool to become a carrier of therapeutic genes in precision therapies such as gene therapies and messenger RNA (mRNA) based therapies. These therapies often require pDNA for both viral vector production and mRNA synthesis.

The challenge with gene therapies is that many are designed for a small number of patients. This makes it impractical for individual companies to invest in large-scale, capital-intensive manufacturing equipment. CDMOs, on the other hand, who cater to the requirements of multiple companies, can develop platform processes that achieve the much-needed economy of scale. This makes CDMOs vital players in pDNA production for precision therapies.

Prioritizing quality in Precision Therapies

Within the realm of precision therapies, the concept of quality isn’t merely a catchphrase but an absolute necessity. Regulatory agencies, such as the Food and Drug Administration (FDA) in the USA and the European Medicines Agency (EMA), have set stringent manufacturing criteria. These criteria are intricately linked to the intended application of pDNA, whether it serves as an active pharmaceutical ingredient (API), as in the case of DNA vaccines, or functions as an intermediary raw material, for instance, in the production of viral vectors or mRNA.

As a result, manufacturers have to adopt a risk-based approach to ensure the entire process adheres to the appropriate grade and phase requirements. This approach encompasses meticulous documentation, comprehensive validation, and rigorous traceability measures. The emphasis on quality extends beyond the pDNA employed in the manufacturing process — it also includes the influence on the quality of the ensuing viral vectors or mRNA, which constitute indispensable components within the domain of gene therapies.

Challenges in pDNA manufacturing

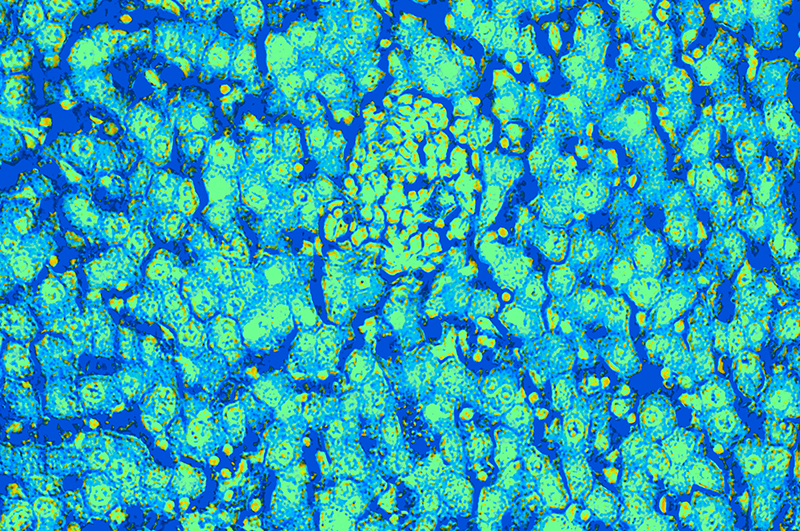

Manufacturing pDNA for precision therapies comes with its own set of challenges. The production process’ yield and purity depend on various factors, including the choice of bacterial strain and the feeding strategy used.

The upstream processes, such as fed-batch profiles and the choice of bacterial strain, are pivotal in determining the final pDNA product’s yield and purity. Managing cell stress and optimizing these parameters is vital for consistent and reliable pDNA production.

Oxygen and temperature also play a role in influencing the supercoiling of pDNA. Supercoiled (SC) pDNA, in comparison to relaxed topological conformations, brings distant sites closer together, making them more biologically active. This superior biological activity is observed both in vitro and in vivo, highlighting the importance of sc pDNA in precision therapies.

The physical and chemical similarities between pDNA, chromosomal DNA (chrDNA), RNA, and endotoxins also present a challenge during purification. The resemblance between critical impurities and pDNA needs to be addressed to ensure the final product meets the required standards.

Another hurdle during pDNA purification is the removal of non-sc pDNA. This is necessary because non-sc pDNA may not exhibit the desired therapeutic properties and could lead to unwanted immune responses. Depending on purity and yield requirements, the purification process may involve three or more steps, including chromatography, anion exchange (AEX), hydrophobic interaction chromatography (HIC), size exclusion chromatography (SEC), and filtration steps.

To address these challenges, scientists at Syngene have developed a proprietary platform process for pDNA. This platform streamlines and optimizes pDNA production while ensuring consistency and quality at any scale (1).

Custom manufacturing approaches to pDNA

As the demand for precision therapies continues to grow, there is an increasing emphasis on using non-animal products during manufacturing. This reflects a broader shift in the pharmaceutical and biotech industry towards more sustainable and ethical practices. CDMOs play a crucial role in accommodating these requirements and developing custom manufacturing approaches that align with customer-specific needs.

Additionally, many aspects of the purification process, including cost, yield, purity, grade, and speed, must be evaluated and often tailored to a customer’s specific needs. This level of customization is essential to meet the unique demands of precision therapies, which often target rare diseases or specific genetic mutations.

Conclusion

With the biopharma industry embarking on Medicine 4.0 and the era of precision therapies, manufacturing pDNA and mRNA has emerged as a crucial aspect of these ground-breaking treatments. CDMOs, with their expertise, flexibility, and commitment to quality, are playing an indispensable role in meeting the challenges posed by small patient populations and the exacting standards set by regulatory agencies. The road to precision therapies runs on innovation and collaboration, and CDMOs are at the forefront of this transformative journey.

Resources

- How Syngene delivered >90% purity pDNA for a global biotech using a proprietary platform process

- Cracking the code: The transformative role of pDNA in Cell and Gene therapy